With the first wave of solar panels approaching their end-of-life stage, there is an opportunity to create greater circularity within the industry

Since the turn of the century, the renewables industry, and particularly ground-mounted solar, has scaled rapidly in order to meet the urgent need to both decarbonise the energy mix and provide additional energy security to the UK. To contextualise, here in the UK, there are 1,336 operational solar farms according to the latest government data, with 142 under construction and a further 1,957 waiting to be built. The growth in solar has been rapid and shows little sign of slowing down.

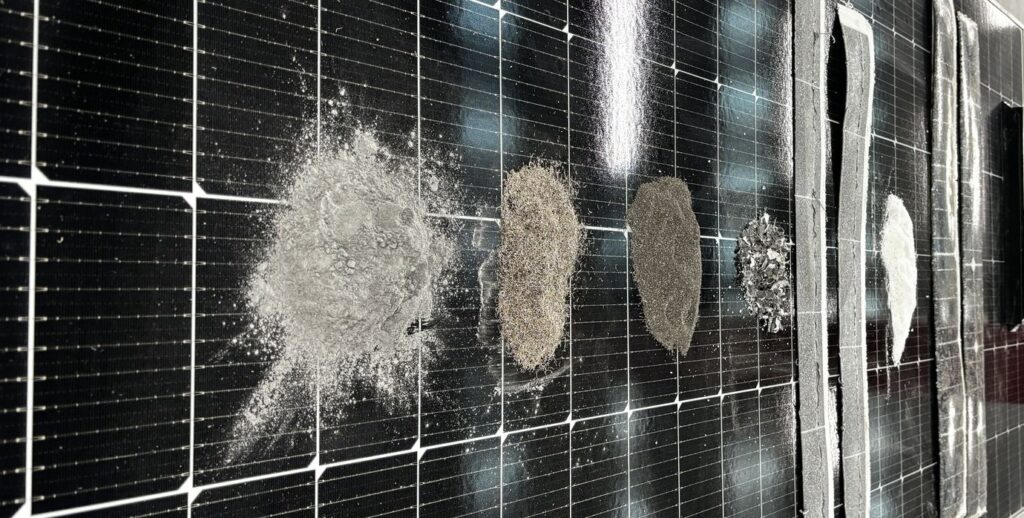

However, as the sector matures and as the first generation of solar assets in the UK approach the end of their operational lifespans (typically, 25-40 years), the sector faces a growing volume of photovoltaic (PV) waste. This, paired with limited recycling infrastructure and complexities in finding solutions for diverse solar technologies, presents a challenge – and an opportunity – which has been receiving increasing attention from the industry, investors, and the media.

In addition to addressing the potential environmental impact of waste materials, opportunity lies in improving circularity by reusing materials and reducing waste, unlocking both emissions reduction opportunities and value in constituent materials.

By circularity, we are referring to resource efficiency and the minimisation of waste, considering elements such as the durability, re-use, and recycling of renewable energy infrastructure and components.

Having identified this issue, we took the opportunity to proactively address the prospect of industry circularity directly by partnering with Lancaster University to investigate responsible end-of-life practices for the solar industry.

This culminated in the formation of the End of Renewable Asset Life Decisions (ERALD) research partnership which leverages the University’s cross-disciplinary expertise in energy sustainability to explore innovative approaches to circularity in the management of solar assets. The Bluefield Solar Income Fund (BSIF), of which Bluefield Partners act as investment adviser, subsequently dedicated funding to support research and innovation in this area.

Here’s what we’ve learned so far.

Research process

The first project, ERALD I, focused on applying the concept of Materials Passports, a digital tool designed to track the composition of materials and support reuse and recycling, to BSIF’s recently constructed 50MW project, Yelvertoft Solar Farm. The research team mapped the materials and components used onsite, drawing information from a series of collaborative workshops, comprehensive desktop research and manufacturer datasheets.

A site visit to Yelvertoft Solar Farm enabled university researchers to engage directly with experts from the Bluefield Group and the external Engineering and Procurement Contractor (EPC) partner building the site.

The project aimed to:

- Enhance visibility into the material composition of solar assets

- Identify barriers to recycling and reuse across the value chain

- Explore how circularity can be integrated into the development of new assets

- Assess the feasibility of Materials Passports as a tool to support more circular practices

Key findings

The research yielded four main insights:

- Tools like Materials Passports show promise, but their effectiveness depends on broader industry adoption and data transparency from manufacturers

- Circularity requires collaboration – circularity cannot be achieved in isolation. Solutions must be co-developed across the industry and supply chain

- Proactive maintenance plays an important role in extending the useful life of components and optimising resource efficiency during the operational phase of the asset

- Policy evolution is essential – legislative frameworks, such as the EU’s Waste Electrical Electronic Equipment (WEEE) Directive, which focuses on electrical and electronic waste, must adapt to support circular practices in the renewables sector

Next steps

Following the conclusion of ERALD I, BSIF funded a second phase of research with the Lancaster team, which will take a more holistic view of the solar value chain. This project aims to map current practices, identify systemic barriers to a circular industry and propose a roadmap for future research, innovation and policy engagement. The findings, expected in July 2025, will inform BSIF’s internal circular economy strategy and contribute to wider industry dialogue.

As Investment Adviser, Bluefield has continued to assess the practical application of Materials Passports across the development, construction and operational phases of the asset lifecycle. Externally, we have been engaging with supply chain partners and industry bodies to raise awareness, encourage participation, and foster a collaborative approach to circularity.

In conclusion

Bluefield’s partnership with Lancaster, the ERALD project, was recognised at the Environmental Finance Sustainability awards, where we won the ‘ESG Innovation of the Year (research)’ award.

This was a wonderful acknowledgement of the work undertaken thus far, and of our ambitions for the ERALD project more broadly.

However, it’s important to acknowledge that achieving circularity in any industry is a complex, long-term objective and one that has a lot of moving parts.

As the demand for renewable energy infrastructure increases, it is increasingly important for companies to plan not only for the construction and operation of their assets, but also for the processing of equipment at the end- of-life. The ERALD research represents an early and important step in building the knowledge base and partnerships required to support a more sustainable and resource-efficient energy system.

We are at the beginning of what is, hopefully, a fundamental shift in our industry and how we approach end-of-life decommissioning. The concept of ‘end-of-life’ presents challenges, as it implies linearity, that this is an issue for the future. However, through our work with Lancaster and by considering the full supply chain, Bluefield hopes to pinpoint areas for improvement and identify ways to work together as an industry to move toward a circular economy.